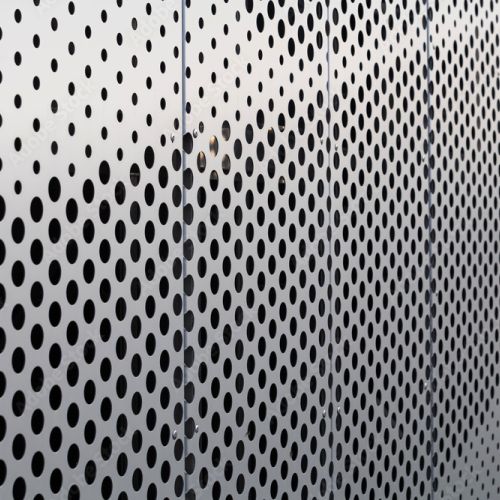

Perforated Aluminium

Perforated aluminium sheets are flat panels of aluminium that have been mechanically punched or stamped with a pattern of holes, shapes, or slots. These sheets are valued for their aesthetic appeal, versatility, and functional properties. They are widely used in various industries for both decorative and practical purposes.

Manufacturing Process

- Material Selection:

-

- Sheets are typically made from high-quality aluminium alloys, such as 1050, 3003, 3105, 5005, 5754, depending on the required strength, corrosion resistance, and workability.

- Perforation:

-

- Punching: Mechanical or hydraulic presses with dies are used to punch holes in the aluminium sheet. This method is suitable for high-volume production with consistent patterns.

- Laser Cutting: Laser cutting offers high precision and flexibility, allowing for intricate designs and custom patterns.

- Finishing:

-

- Deburring: Removal of burrs and sharp edges resulting from the perforation process.

- Surface Treatments: Options include anodizing, powder coating, and painting to enhance corrosion resistance, appearance, and durability.

Hole Patterns and Configurations

- Round Holes: The most common and versatile pattern, used for general purposes.

- Square Holes: Provides a modern look, often used in architectural applications.

- Slotted Holes: Offers directional air or light flow, used in ventilation and filtration.

- Hexagonal Holes: Creates a honeycomb pattern, combining strength with lightweight properties.

- Custom Shapes: Tailored to specific design requirements, including logos, decorative motifs, and unique patterns.

Properties

- Lightweight: Aluminium’s low density makes perforated sheets easy to handle and install.

- Corrosion Resistance: Aluminium naturally forms a protective oxide layer, which can be enhanced with surface treatments for improved durability.

- Strength-to-Weight Ratio: Offers excellent structural strength while remaining lightweight.

- Aesthetic Appeal: Available in various patterns and finishes, providing both functional and decorative benefits.

- Versatility: Suitable for a wide range of applications due to its customizable patterns and sizes.

- Recyclability: Aluminium is fully recyclable, making it an environmentally friendly material choice.

Applications

- Architectural and Design:

-

- Facades and cladding: Enhances building exteriors with decorative and functional elements.

- Interior design: Used for wall panels, ceilings, partitions, and acoustic panels.

- Sunshades and screens: Provides shading while allowing light and air flow.

- Industrial:

-

- Filtration: Used in air, liquid, and oil filtration systems.

- Ventilation: Allows air flow while protecting against debris and contaminants.

- Acoustic control: Reduces noise levels in industrial environments.

- Automotive:

-

- Grilles and vents: Provides ventilation and aesthetic appeal for vehicle exteriors.

- Heat shields: Used to protect components from high temperatures.

- Agricultural:

-

- Sieves and screens: Used for sorting and processing agricultural products.

- Protective barriers: Protects crops and livestock from pests and environmental factors.

- Furniture and Fixtures:

-

- Shelving and storage units: Combines functionality with modern design.

- Lighting fixtures: Used in decorative and functional lighting applications.