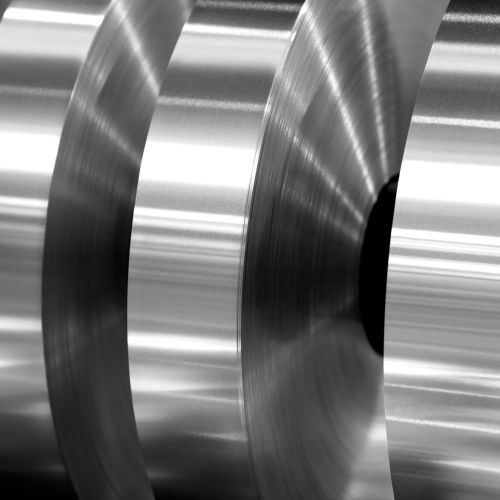

Mill Finish Aluminium Sheets & Coils

A mill finish on aluminum refers to the surface quality of aluminum products (like coils or sheets) directly after they have been processed at a rolling mill, without any additional polishing, coating, or finishing treatments. This finish is the product’s raw, untreated state, which may include natural oxide layers, minor surface roughness, and slight imperfections from the manufacturing process.

Product Types

- Aluminium Sheets: Typically ranging from 0.2mm to 6mm in thickness, sheets are used in applications like automotive panels, building facades, and packaging.

- Aluminium Plates: With thicknesses greater than 6mm, plates are ideal for heavy-duty applications such as aerospace, military, and marine industries.

- Aluminium Foils: Thinner than 0.2mm, foils are commonly used in packaging, insulation, and electrical applications.

Alloy Options

Flat rolled aluminium products are available in various alloy compositions, each tailored for specific properties and applications. Here are some common alloy series and their characteristics:

- 1xxx Series (Pure Aluminium):

-

- 1050: Often used in food packaging, heat exchangers, and electrical conductors.

- 1100: Common in industrial applications, particularly for signs, decorative uses, and cooking utensils.

- 3xxx Series (Manganese Alloys):

-

- 3003, 3103: One of the most popular alloys, used for cooking utensils, storage tanks, and decorative uses.

- 3105: Common in residential aluminum siding and roofing.

- 5xxx Series (Magnesium Alloys):

-

- 5052: One of the most widely used alloys, ideal for marine environments, chemical tanks, and pressure vessels.

- 5083: Known for its excellent performance in extreme environments, often used in the construction of ships and boats.

- 5754: Used in automotive, truck, and general industrial applications where both corrosion resistance and formability are required.

- 5005: Highly rigid and increased corrosion resistant option for construction.

- 6xxx Series (Magnesium and Silicon Alloys):

-

- 6061: One of the most versatile and widely used alloys, found in construction, aerospace, and automotive applications.

- 6063: Used in architectural applications like window frames, doors, and irrigation tubing.

- 6082: A high-strength alloy, often used in structural applications and bridges.

- 7xxx Series (Zinc Alloys):

-

- 7075: Known for its high strength and used in aerospace, military, and other critical applications.

- 7050: Often used in aerospace for structures requiring high strength and resistance to stress-corrosion cracking.

6. 8xxx Series (Mix):

-

- 8006,8011: Used in food and beverage packaging, especially in aluminum foil.

- 8090: Lightweight alloy used in aerospace and military applications.

Applications

Mill-finish aluminum products are used in a wide range of industries. Some common applications include:

- Architectural and Construction: Mill-finish aluminum sheets and coils are often used in the construction of facades, roofing, siding, and cladding. It’s also used in structural applications like window frames, doors, and curtain walls. In some cases, mill-finish aluminum is used as-is, while in others, it’s further treated for appearance or protection (e.g., anodizing or powder coating).

- Automotive: Mill-finish aluminum is used in the automotive industry for components such as body panels, structural elements, and heat exchangers. It’s valued for its strength-to-weight ratio and durability.

- Packaging: Aluminum foil products are sometimes supplied in a mill-finish form, especially in applications like food packaging where a further finish is not required.

- Electrical: Mill-finish aluminum is also used in electrical applications, including conductors, bus bars, and components for electrical circuits due to its high electrical conductivity and resistance to corrosion.

- Consumer Products: Some consumer products, like kitchen appliances, cookware, and electronics, can be made from mill-finish aluminum, especially if further surface treatment is not necessary.

Advantages

- Cost-Effective: Because mill-finish aluminum hasn’t undergone additional finishing steps, it is often less expensive than anodized, painted, or polished aluminum products.

- Corrosion Resistance: Even in its raw state, aluminum’s natural oxide layer provides inherent corrosion resistance, making it suitable for outdoor and exposed applications.

- Versatility: Mill-finish aluminum is available in a range of alloys, offering a good balance of strength, formability, and corrosion resistance for many industries.

- Ease of Further Processing: Mill-finish aluminum can be easily further processed (e.g., anodizing, powder coating, or polishing) depending on the needs of the specific application.

Post-Finish Options

Mill-finish aluminum products can be further processed to improve their aesthetic or functional properties:

- Anodizing: An anodized aluminum finish enhances the natural oxide layer, providing increased corrosion resistance and allowing for color options. It also improves surface hardness and durability.

- Powder Coating: Aluminum sheets and coils can be powder-coated to improve appearance, provide color, and offer additional corrosion resistance.

- Polishing: Some mill-finish aluminum products are polished to a shiny, mirror-like finish for decorative applications.

- Painting: Mill-finish aluminum can be painted for additional protection and aesthetic improvement.